If you have begun new construction on a facility that suits your needs, odds are good that you have already had to make a number of important decisions about how that building is coming together. One of the decisions you may not have tackled yet is selecting a cooling tower. With a wide variety of options and setups available, it can feel overwhelming to decide on this vital piece of equipment for fear that you will come to regret your choice later.

However, picking a cooling tower in new construction does not need to be difficult, and you can narrow your selections by considering some important factors that are unique to your situation. Before you make your choice, consider the following points.

Picking A Cooling Tower: Important Considerations

Cooling towers come in all shapes and sizes, but they function in much the same way across the board. However, you can choose between some fine-tuned details in order to acquire the machinery that will work best for your particular situation. One choice that can start the process is whether you would like an open loop or closed loop system; from there, your options will narrow and become easier to parse.

As the name suggests, an open loop tower is open to the world, which means that if you are building in an area where debris might be a problem (such as nearby a forest or another factory), a closed loop system might be in your favor. However, closed loop systems are typically more expensive up front than their open loop counterparts; if you select open loop, be prepared for increased filtration and rigorous cleaning to keep the system from fouling.

Factory Assembly Or Field Erection

The next question to answer is whether you want to purchase a tower that has already been put together at a factory, then shipped to you ready to hook up, or whether you need a field erected system that is built on-site with custom parts. Field erected towers are generally more powerful on average, so if you have significant heat transfer needs, this may be the route to take. In general, facilities with a heat rejection load less than 1400 tons typically fare just fine on factory assembled equipment; those in excess of 5000 tons will struggle to find anything suitable that is not field erected. In between, you will need to consider other factors.

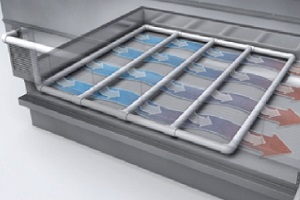

Crossflows And Counterflows

Crossflow and counterflow refer to the two configurations that water can come into contact with the source of heat transfer in your system. Crossflow, as the name suggests, distributes water across (that is, intersecting with) the way the air flows in the system. Counterflow, in contrast, runs parallel (though in the opposite direction of the airflow). Crossflow towers tend to be more efficient and easier to service, but they take up a lot more space. If you are limited in workable area, or if you must construct your tower near a wall, a counterflow setup may benefit you more.

Selecting Sweeper Piping

Sweeper piping is not a requirement on cooling towers, but it is highly recommended that you select a tower that is compatible with a sweeper system. This will help to reduce the buildup of sediment on the bottom of your tower. If you are purchasing a factory cooling tower rather than constructing one in the field, be sure to include sweeper piping during assembly.

Sweeper piping is not a requirement on cooling towers, but it is highly recommended that you select a tower that is compatible with a sweeper system. This will help to reduce the buildup of sediment on the bottom of your tower. If you are purchasing a factory cooling tower rather than constructing one in the field, be sure to include sweeper piping during assembly.

Thoughts On Construction Materials

You will be faced at some point with the decision about what material your tower is made out of. In general, galvanized steel is the cheapest option, but it is also the one with the shortest lifespan. Stainless steel, fiberglass, polyurethane coated and concrete surfaces can last from 20 to 30 years, but they each come with their own pros and cons, from their resilience to wind to coloring options, UV resistance and warranties. Note that fiberglass towers are not compatible with crossflow systems.

Trust The Experts To Help You Make The Right Choice And Service Your New Tower

Whether you are just starting the process of choosing the right cooling tower for your new construction or you are in the midst of the decision-making process and need some guidance, you do not need to finalize your choice alone. The experts at Tower Water would be happy to help you understand which features are important for a cooling tower at your facility, and we can explain the details and why they matter. Reach out to ask any questions that you may have or to schedule an appointment to meet with us and discuss your goals for your facility.